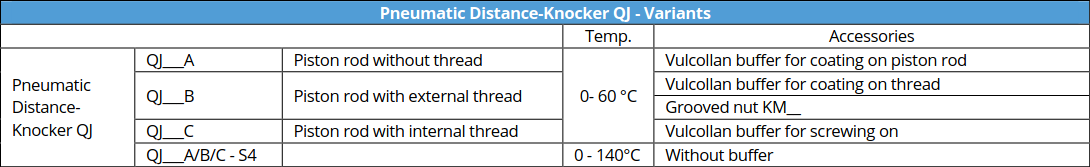

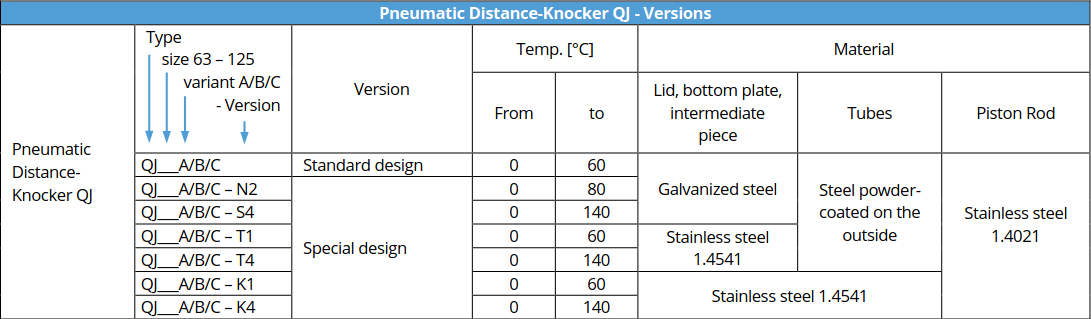

Pneumatic Distance-Knocker QJ

Product properties

.01application

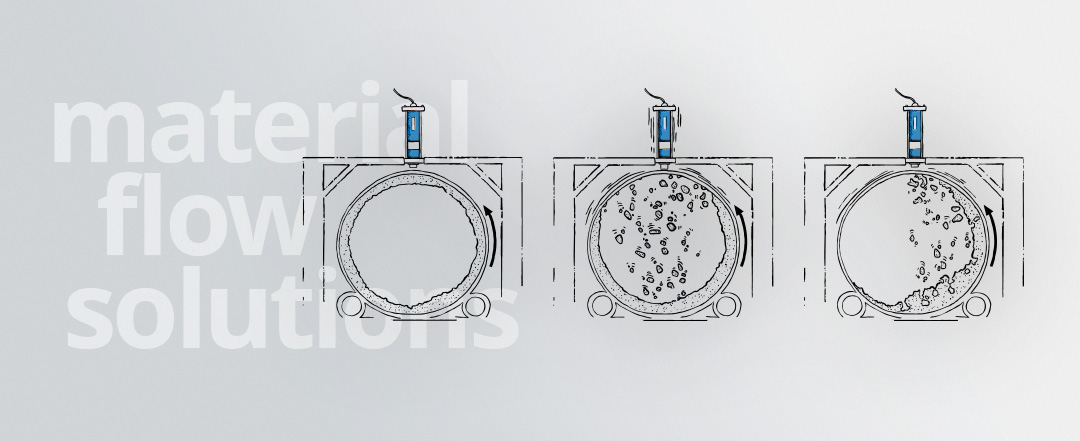

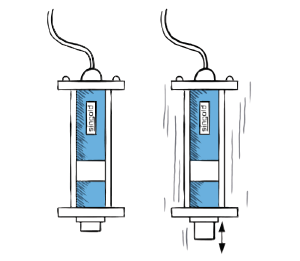

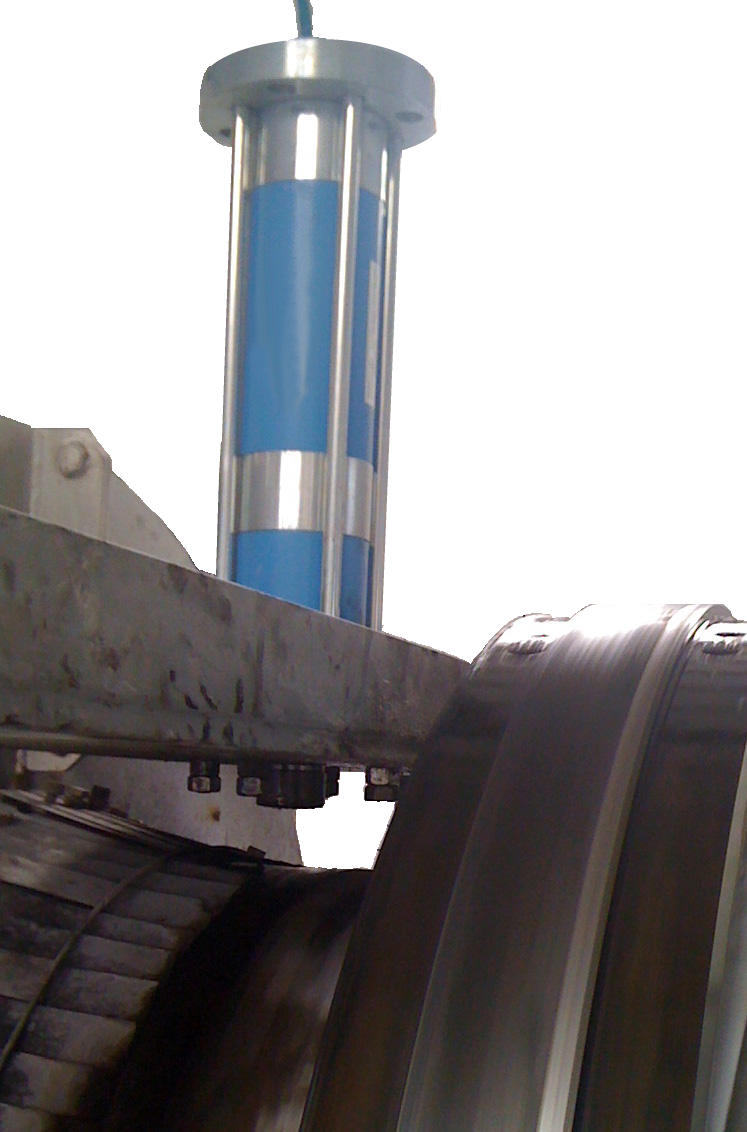

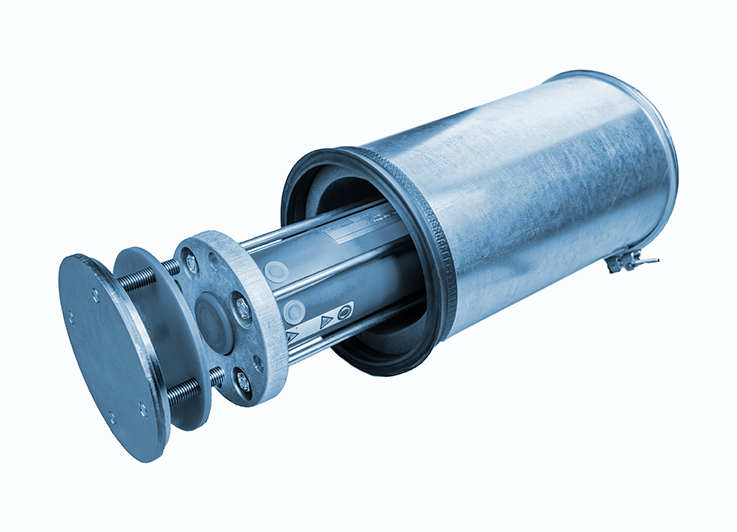

The Pneumatic Distance-Knocker QJ is suitable for knocking against slow-moving drums and filling or emptying stations with moving containers. The knocker type QJ can be mounted at a distance from the rotating drum or a container. The operating principle is identical to the knocker type K, but the impact pulse is transferred to a piston rod which moves to the container. The drum or container wall is touched only briefly during knocking and transmits the impact pulse.

The Pneumatic Distance-Knocker QJ is used, for example, in rotary kilns, drum drying systems, filter cup knocking

stations, centrifuge drum cleaning stations and many other applications.

Detailed information: General description

.02Parameters

With rotating drums, a knocker is fitted vertically from above and strikes at a slight angle against the direction of rotation on a traverse.

Important parameters for the selection of the right knocker:

- Thickness of the container or drum

- Material of the container or drum

- Diameter of the container or drum

- Operating temperature

- If present, insulation thickness for the selection of the mounting

- Protection type for operating environment

For the electrical components:

- Desired operating voltage

- Number of knockers

- Protection type for operating environment

For help in selecting the right knocker, please send us the completed questionnaire. Any drawings, sketches or photos of existing plants are also helpful.

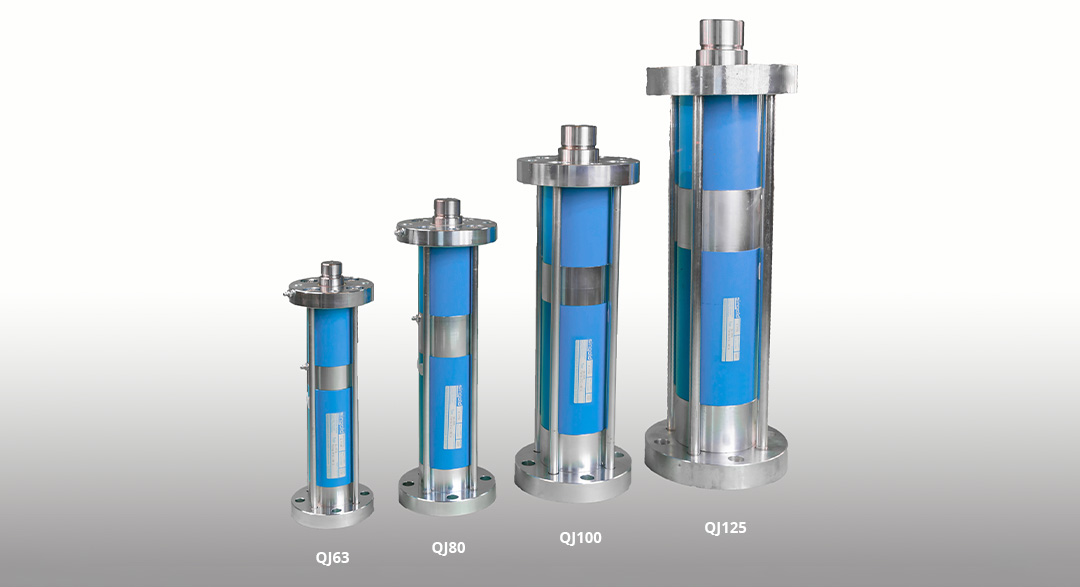

.03Sizes

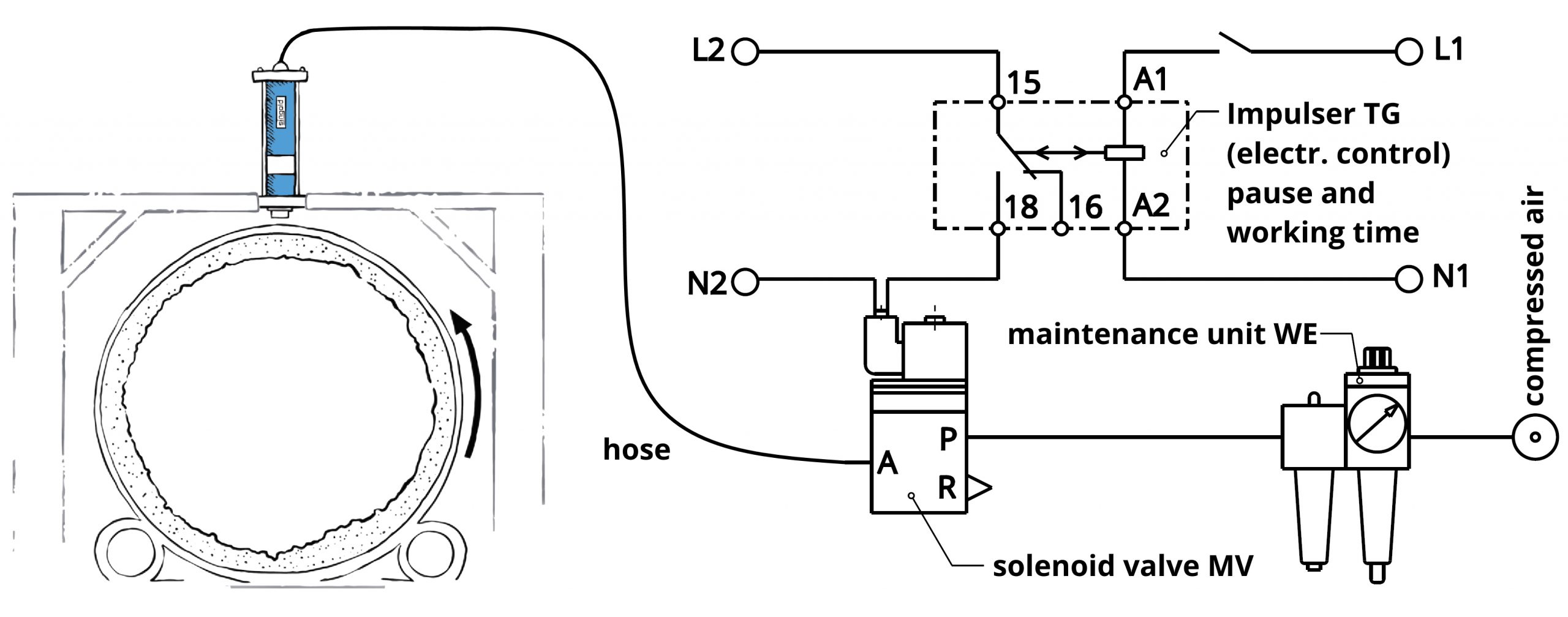

.05Mounting & Operation

The components shown in the picture are required for the installation and operation of the Pneumatic Distance-Knocker:

- Attachment: The Distance-Knocker QJ has to be securely installed to a greater mass (e.g. machine-construction, U-steel filled with concrete) to cover the recoil.

- Electrical control for solenoid valve to desired control voltage. An existing PLC control can also be used.

- Pneumatic connectors and cables

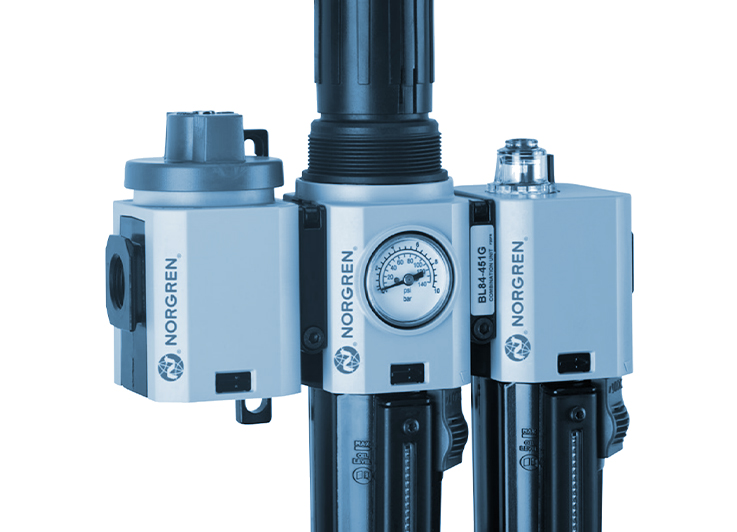

- Maintenance unit for pressure reduction to 3.5 bar operating pressure, drainage and lubrication of the knocker is recommended.

Choose the right knocker for your application

We have two types of knockers in our range: our classic ‘singold’ Pneumatic Knocker Type K is suitable for many applications in which the knocker is attached to the silo wall. The special developed Pneumatic Distance-Knocker Type QJ is suitable for knocking from a distance against slow-moving drums and filling or emptying stations with moving containers.

Suitable accessories for

your Pneumatic Distance-Knocker.

Pneumatic Valves

Electrical Controls

Sound Insulation

Maintenance Units

We optimise your material flow

Contact us

Taking your individual situation into account, we are happy to assist you.