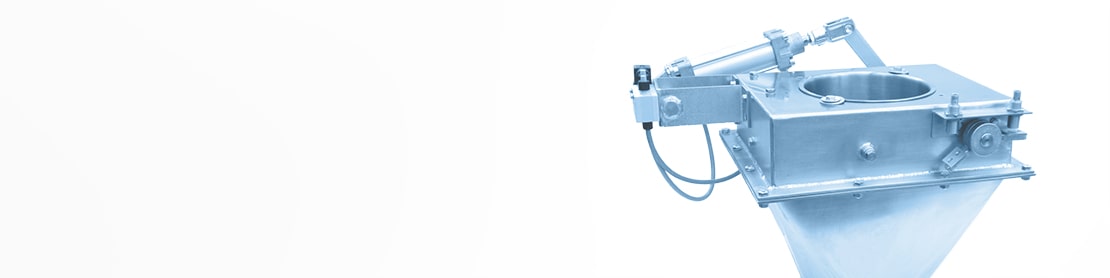

Flap shutter from singold: lightning fast, enduring, low-maintenance

The flap shutter from singold gerätetechnik gmbh is an advanced version of the conventional pendulum flap. The flap shutter is used for the complete unloading of containers and bulk material of all kinds. Examples include hopper scales, primary and secondary vessels in mixing plants, wagons, reservoirs under filters and separators and cone worm mixers.

Sophisticated mechanics

The flap shutter from singold gerätetechnik gmbh was developed with the highest level of engineering. Thanks to its ingenious mechanics, the flap shutter first moves vertically downwards and then quickly swings completely to the side out of the product flow. This minimizes wear, especially with abrasive materials. The bulk material is neither damaged nor modified, nor is there wear on the flap shutter. This and its lubrication-free slide bearings make the flap shutter from singold an extremely enduring and low-maintenance device. Even with manually operated designs, large nominal widths with a high flap load can be opened quickly with little physical effort. Erwin Lüer, the company founder, applied for the patent of this innovative design in the 1970s.

Custom-made solutions for every application

The flap shutter is available in different materials, designs, and closing forces. Therefore, it can be used everywhere, where there is a need for shredding, sifting, drying, grinding, or sorting. The range of applications is enormous: from waste sorting and waste incineration to the mining of salt, bromine, lithium and titanium to the production of wood fibers or fertilizers. The flap shutter has achieved particular importance in the glass industry, for example in Zippe’s recycling and batch plants.

If two flap shutters are arranged one above the other, a double flap shutter is obtained. This is helpful when bulk materials are conveyed to a different pressure level, for example when discharging from cyclones.

The closing force of the flap shutter can hold up to a 5 m water column. A special version is available for use at high temperatures (up to 350 °C).

We are happy to advise you on the selection of the ideal version for your company.

We optimise your material flow

Contact us

Taking your individual situation into account, we are happy to assist you.