Distance-knocker QJ from singold: Engineering at its very best

The pneumatic distance knocker from singold gerätetechnik gmbh is a unique product and the result of the highest level of engineering – well thought out down to the smallest detail. It was developed by the company’s founder Erwin Lüer, whose pneumatic knockers remain the most powerful on the market today.

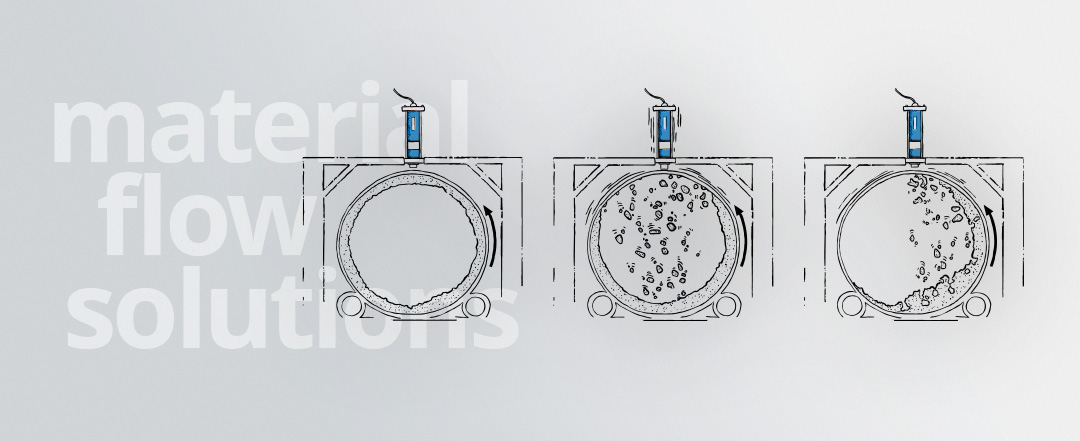

Mode of action

The distance-knocker QJ is based on the simple, yet ingenious idea of the pneumatic knocker.

Spontaneously released energy stored in the form of compressed air, accelerates the percussion piston, which is designed as a permanent magnet. The piston hits a mobile impulse part, which is strongly accelerated after the impulse set and transfers the energy to the element to be knocked off. This process occurs at such a high speed that it is barely visible to the human eye.

Due to its additional impulse part, the distance-knocker QJ broadens the application possibilities when compared to the conventional pneumatic knocker. This special feature allows it to be installed at a distance from the object to be knocked off.

Possible applications

The distance-knocker QJ is universally applicable wherever successful cleaning can be achieved by a hammer blow however, directly mounting a conventional knocker is impossible due to movement or temperature. Therefore, the QJ is the ideal choice for filling and emptying stations with changing containers, slowly rotating drums and hot surfaces. Depending on its size, the piston rod bridges a distance of 25–35 mm to a container or a rotating drum.

The piston rod is also available in an extended version in which the highest possible knocker distance can be increased for example in the case of hot surfaces. With a longer piston rod, the distance of the knocker can be increased by another 200 mm. Thus, it is ideally equipped to knock off, e.g., rotary kiln drying systems with surface temperatures of up to 300 ° C and more.

The QJ is also used with devices for the automatic knocking off of filter cups or filter baskets of different sizes. With its threaded design at the end of the piston rod, the impact body and therefore, the impact geometry can be individually adapted to immeasurable applications. The maximum operating temperature of the knocker is 140° C. A knocker should not get any warmer, to keep the seals etc. from wearing out prematurely.

Effective and demand-oriented knocking

The distance- knocker QJ works with twenty times as much impact energy as ball housings, for example, which cannot be switched off when the drum is rotating, even if they are currently not being used for the process. The distance knocker, by contrast, can knock on demand: If it is not needed, it can be simply turned off. This is a significant contribution to noise reduction in factories.

Flexible and variable thanks to several design options

Our distance-knocker QJ is used in numerous industries and types of facilities – from agriculture to cement production to the utilization of raw materials. We offer it in several versions so it can flexibly fit in different applications. Different models with and without thread and flat spanners, with extended piston rods and/or Vulkollan buffers are available.

Simple and ingenious – simply ingenious

The distance-knocker QJ is ingenious and yet simple in its construction. Therefore, it is low maintenance and if necessary easily disassembled and reassembled.

However, many parameters are important for the selection of the ideal knocker for your application, for example sheet thickness, the gauge of the metal, the kind of material and diameter of the container or drum, the operating temperature and, if applicable, the insulation thickness. We are glad to give you further advice.

We optimise your material flow

Contact us

Taking your individual situation into account, we are happy to assist you.