singold gerätetechnik introduces innovative online configurator

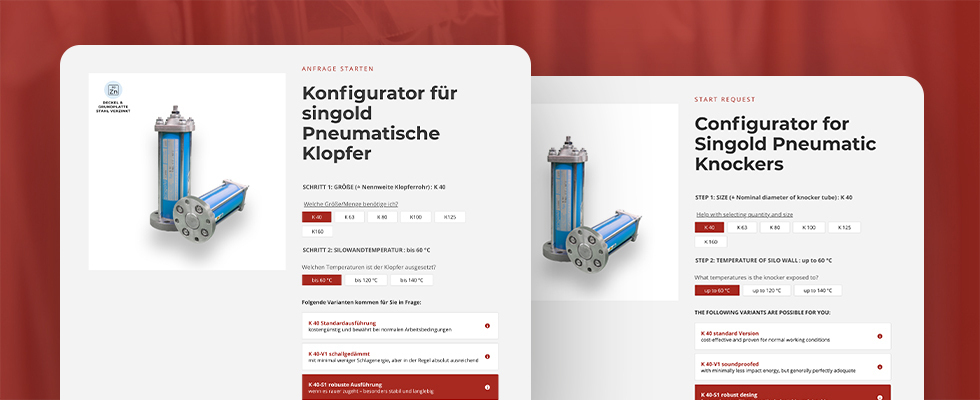

Always focusing on the customer: At singold gerätetechnik, locating and requesting the ideal pneumatic knocker for any purpose has never been simpler. An innovative online configurator has been developed for this purpose. This tool guides the customer step by step through all the relevant query parameters.

Find the right knocker simply, quickly and efficiently

Which knocker do I need for a particular sheet thickness? How many? Which is the right knocker for high ambient temperatures? And which design is suitable for applications in the pharmaceutical and food industries? In the singold online configurator, the customer is shown the appropriate product preselection with just a few clicks. Complicated tables for the time-consuming search for the optimum solution are now a thing of the past. And if you already know which model you need, you can use the configurator to send a request at lightning speed.

The most important parameters with just a few clicks

What type of knocker and how many are required depends primarily on silo size and sheet thickness. An interactive diagram in the online configurator shows the appropriate number and size. In the second step, the application temperature is defined. For applications at temperatures above 60 °C, the tool suggests knockers with aluminium pistons instead of plastic ones. The right pneumatic knocker can even be selected for wall temperatures of up to 140 °C and special application situations such as those involving aggressive dusts and vapours.

singold pneumatic knockers: sustainable, effective and cost-efficient

singold has always relied on pneumatic knockers to eliminate material flow disruptions. This is because, unlike high-speed vibrators and shakers with soft sinusoidal vibrations or devices for blowing into the silo, the pneumatic knocker provides a sustainable and effective solution. Even more than 50 years after company founder Erwin Lüer developed the world’s first pneumatic knocker of its kind, singold knockers are still the most powerful on the market. They cause the silo outlet to vibrate without causing dents that would lead to further problems with material flow. This is because the knocker is only used when it is truly needed: maximum effectiveness with the greatest possible material protection! This relieves the strain on the weld seams, which would otherwise fatigue with constant vibration oscillations.

Try out the online configurator here!

The singold online configurator works on desktop PCs, laptops and smartphones. Try it out for yourself: Link.

We optimise your material flow

Contact us

Taking your individual situation into account, we are happy to assist you.