Start Request

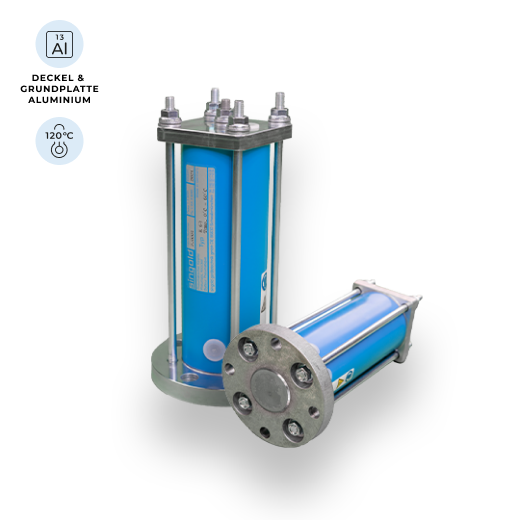

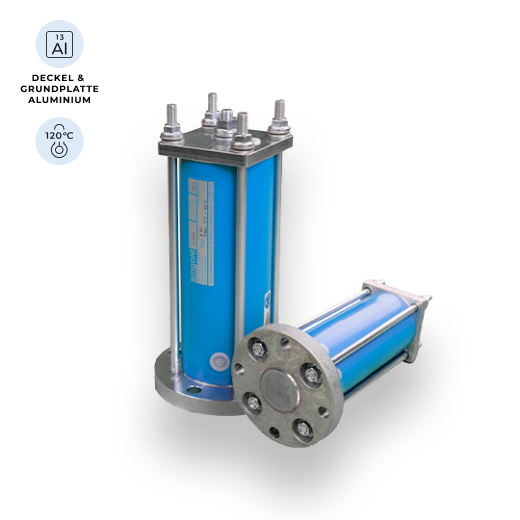

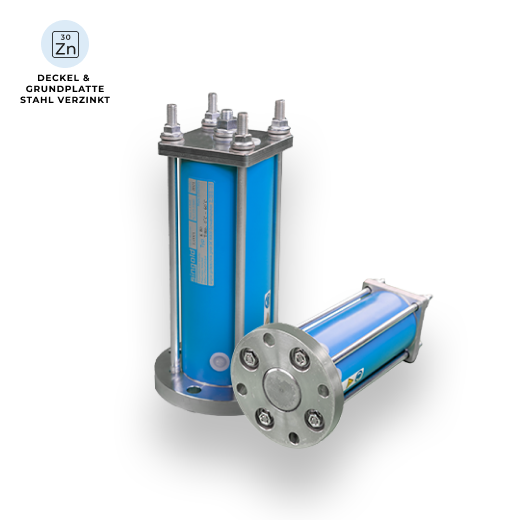

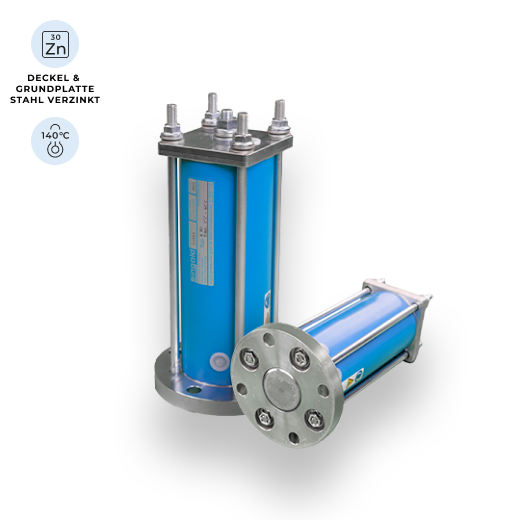

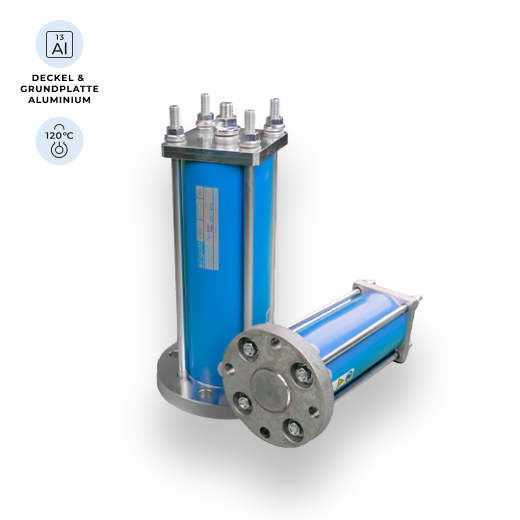

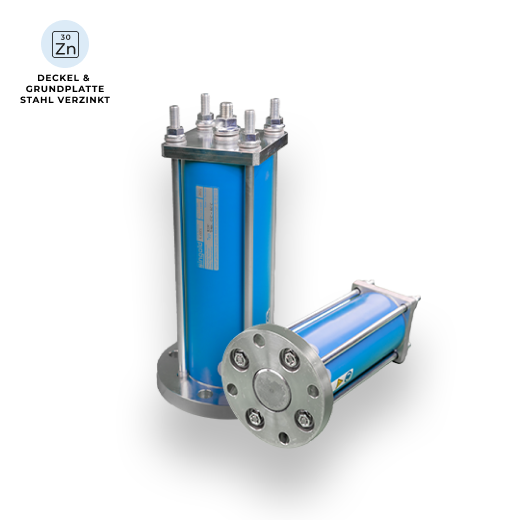

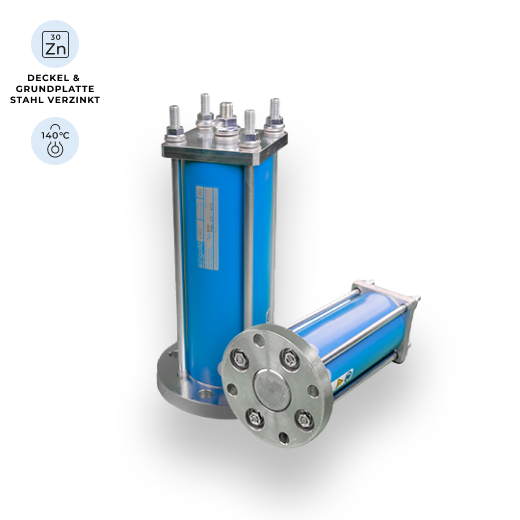

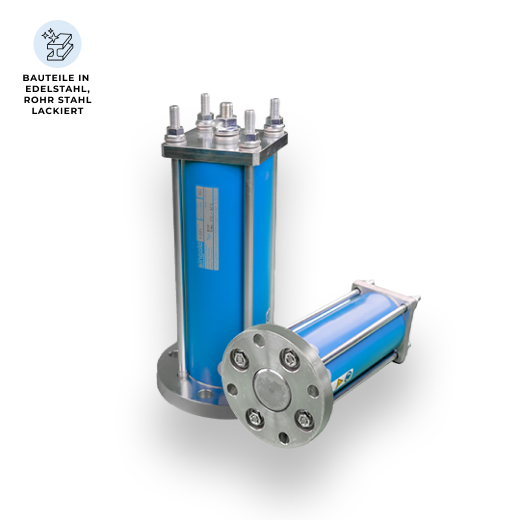

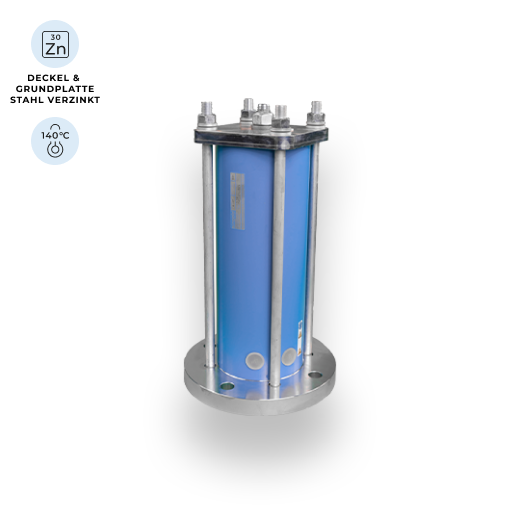

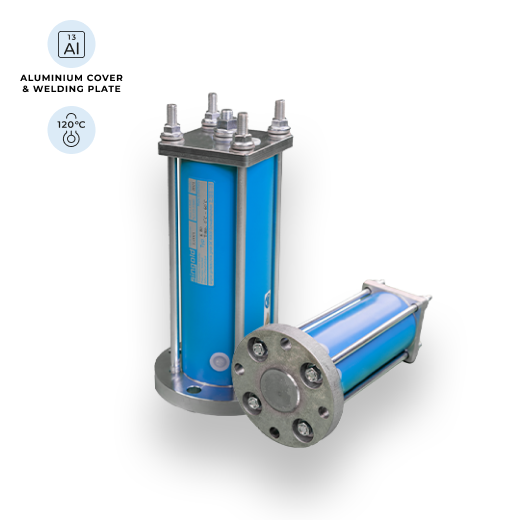

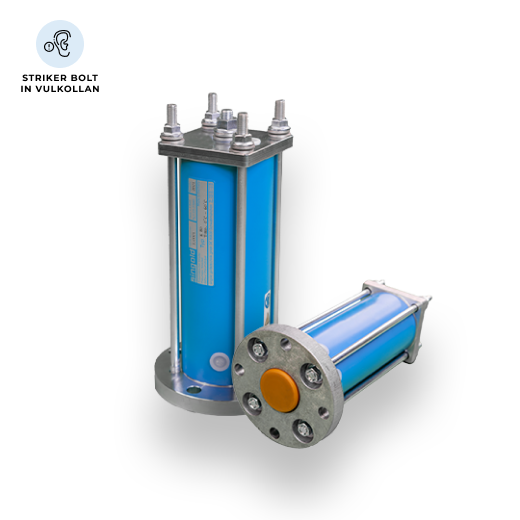

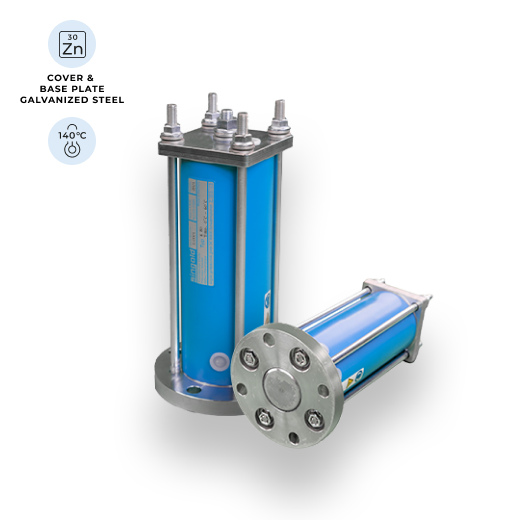

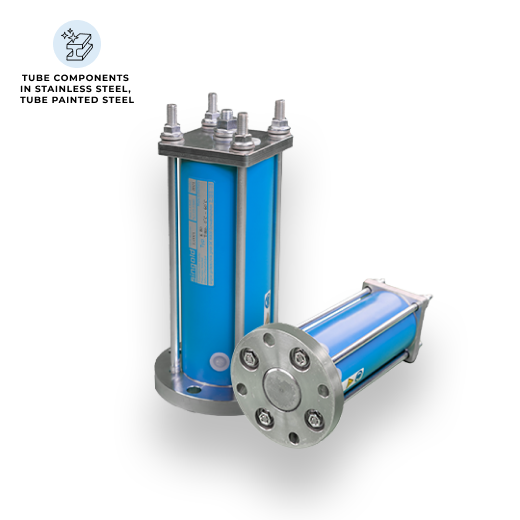

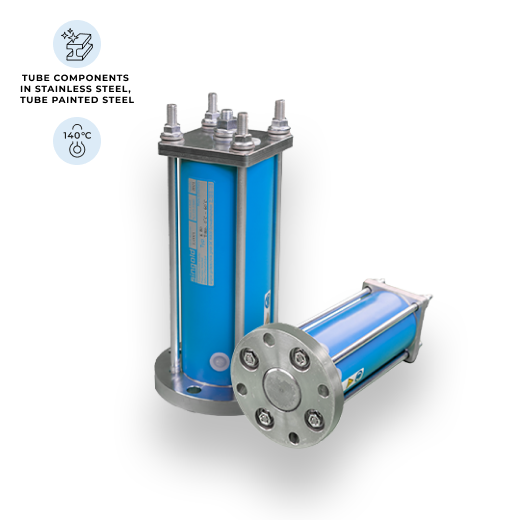

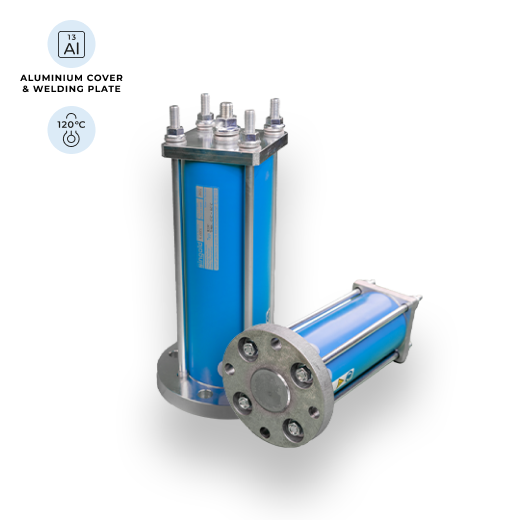

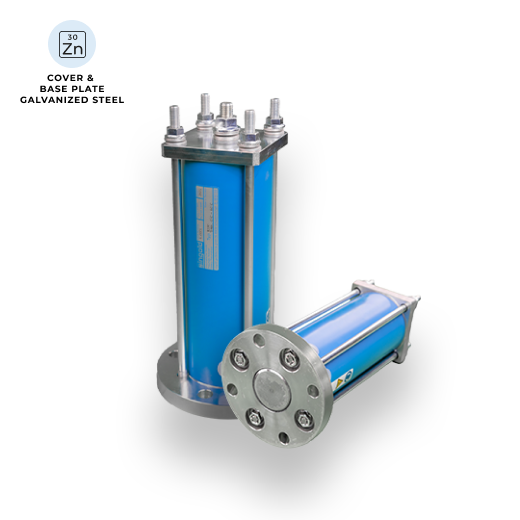

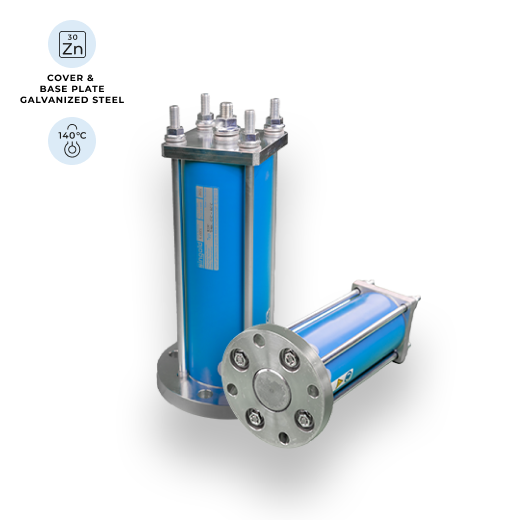

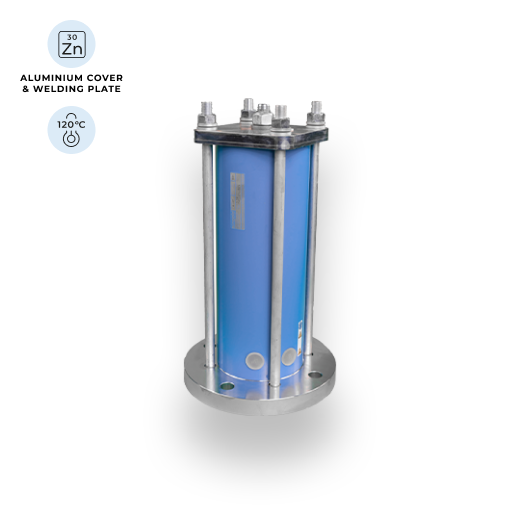

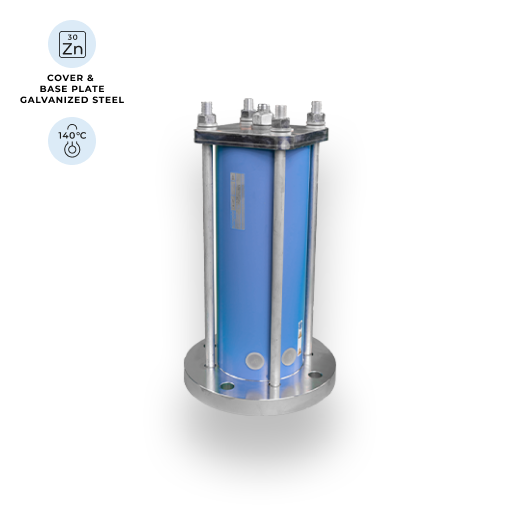

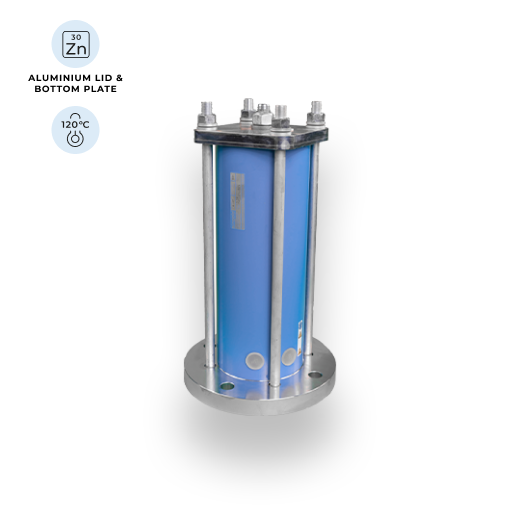

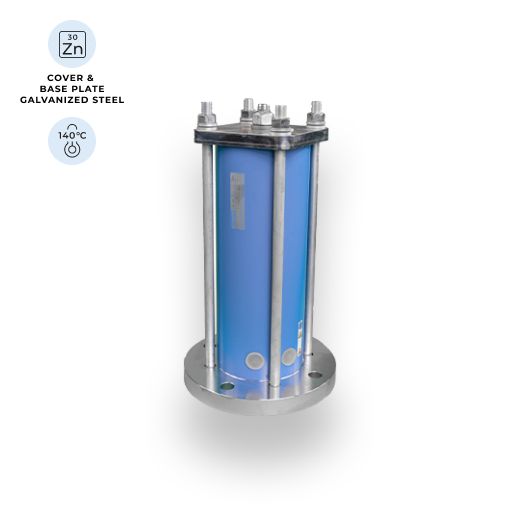

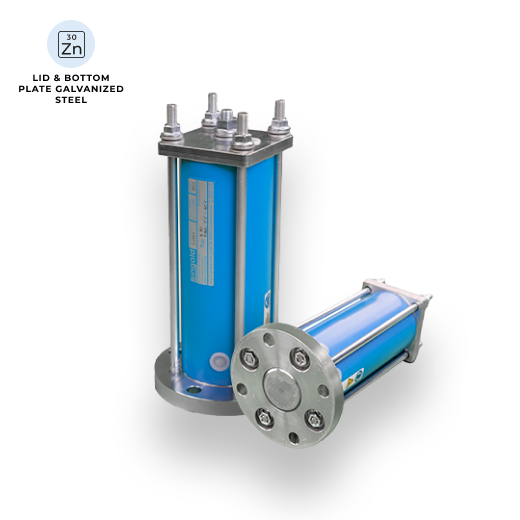

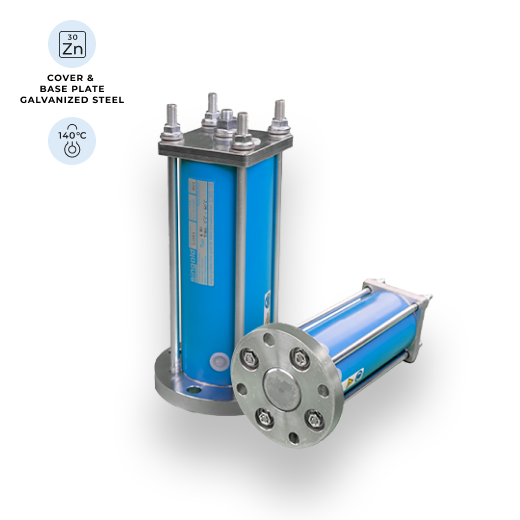

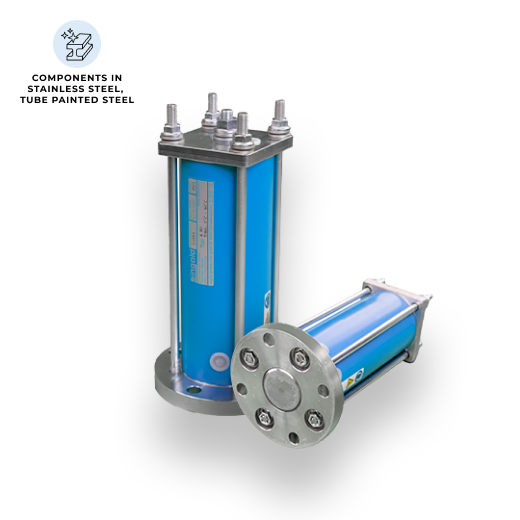

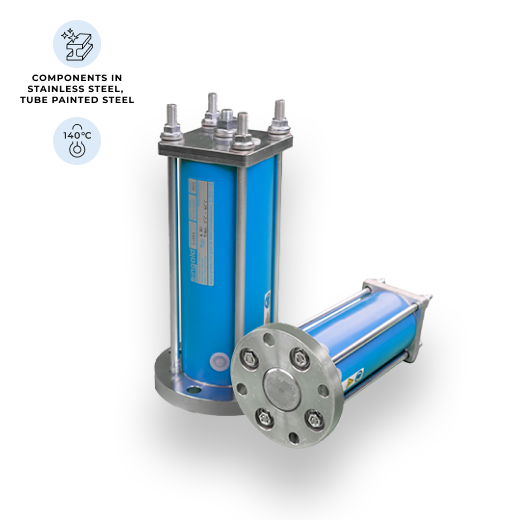

Configurator for singold Pneumatic Knockers

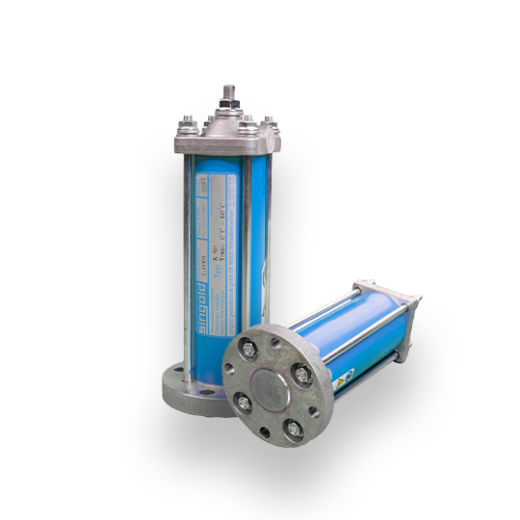

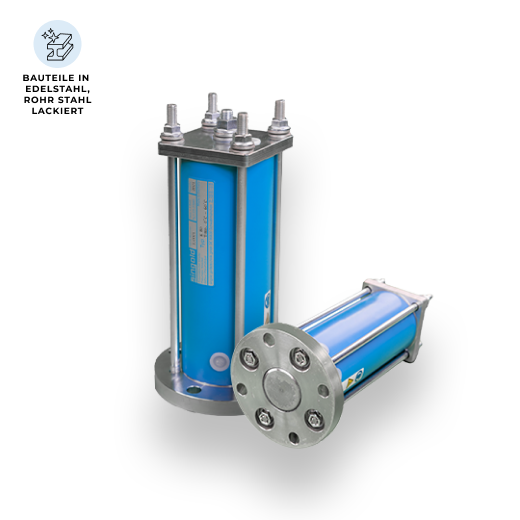

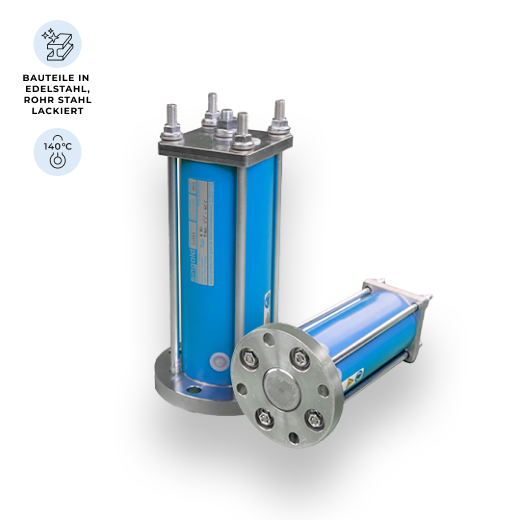

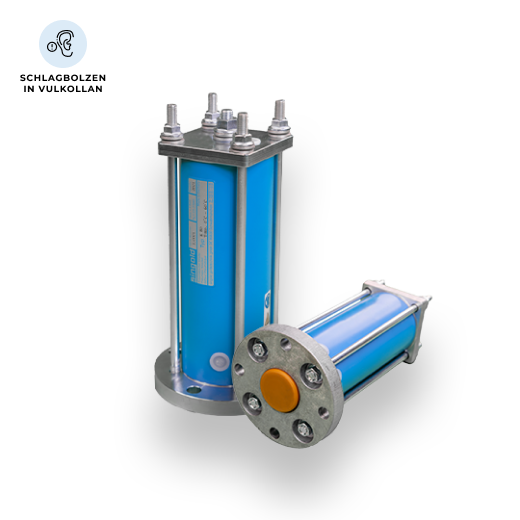

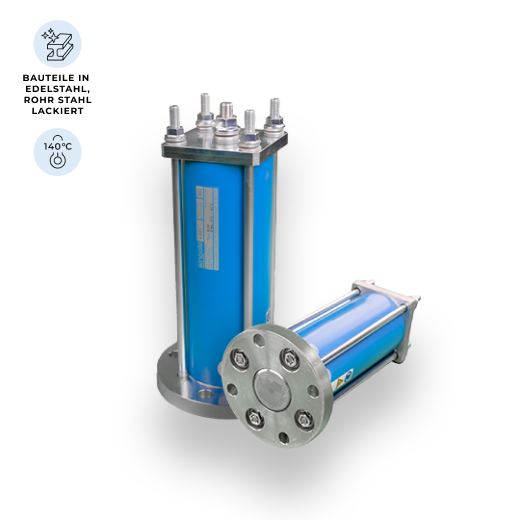

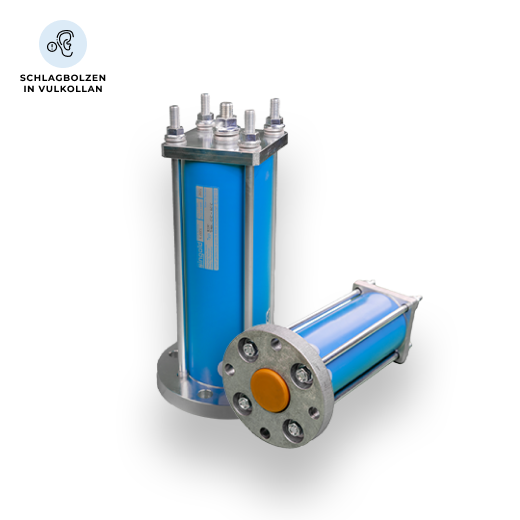

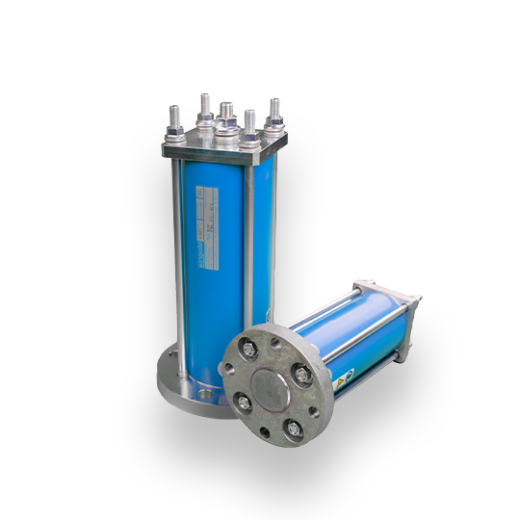

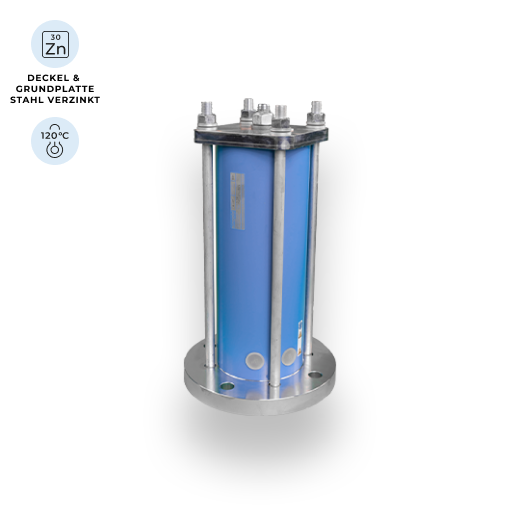

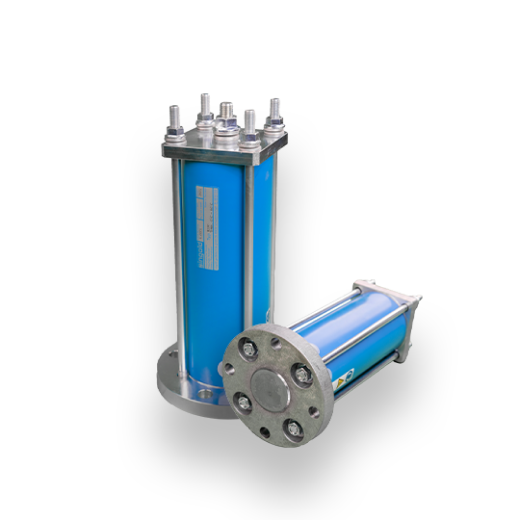

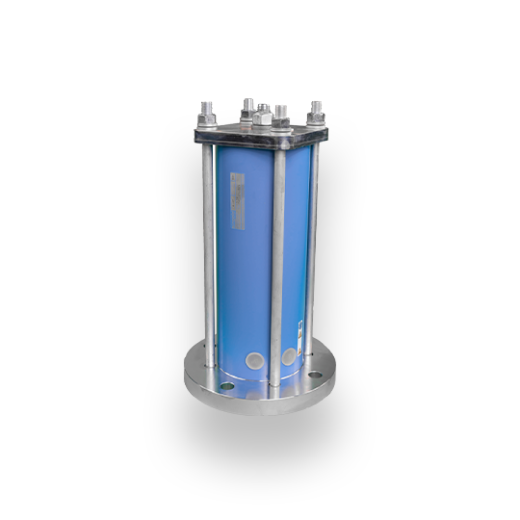

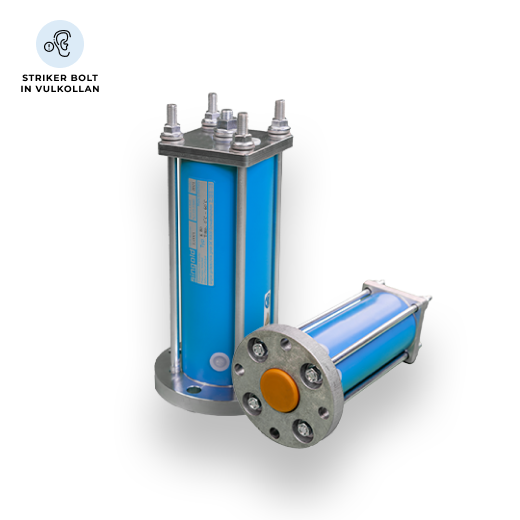

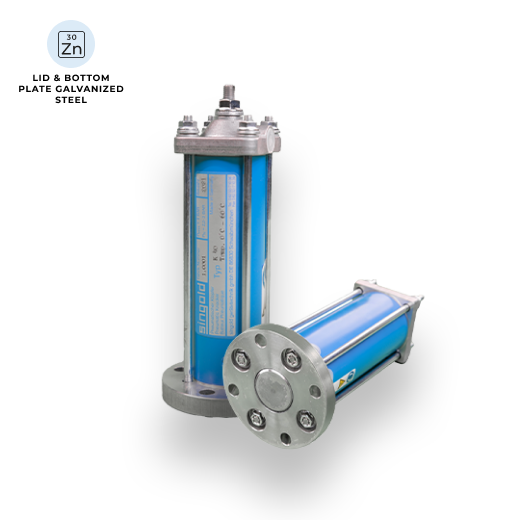

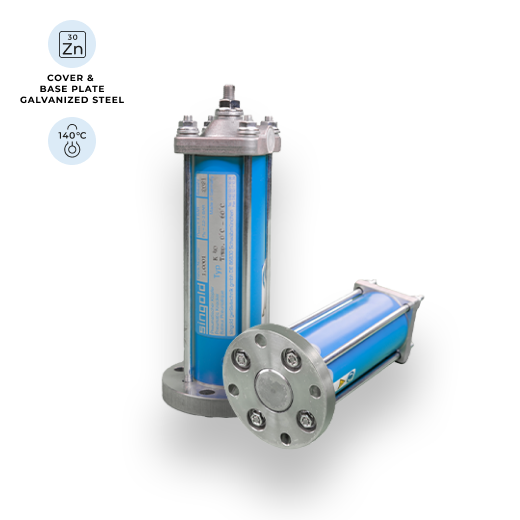

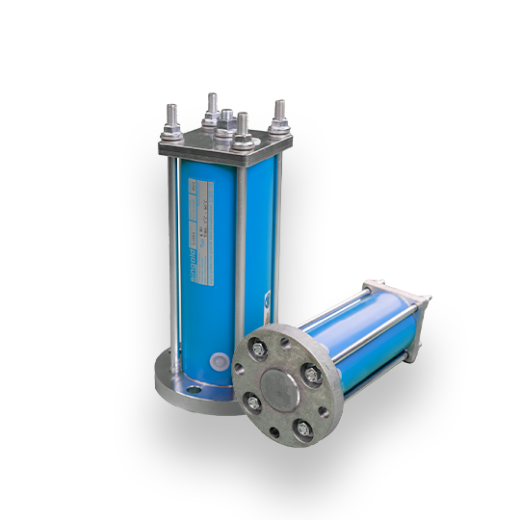

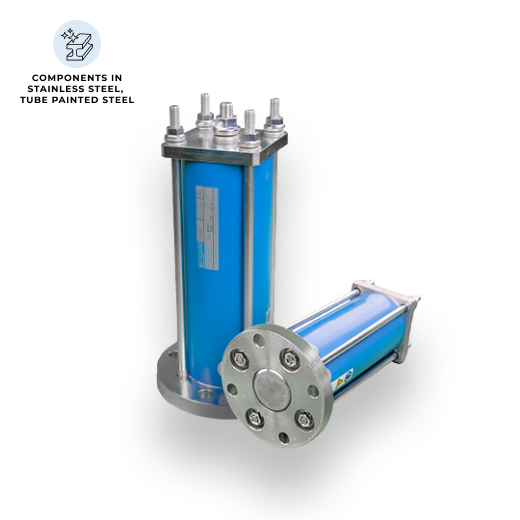

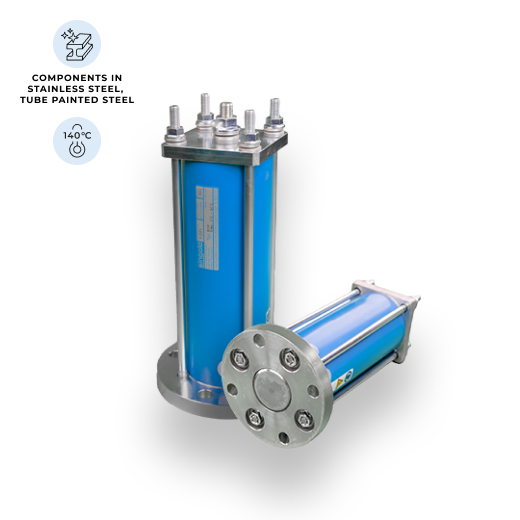

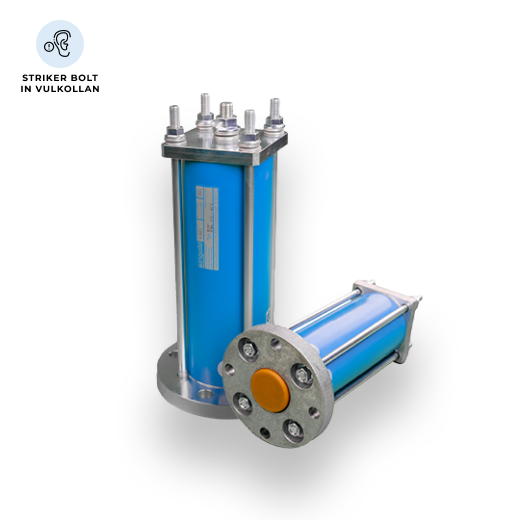

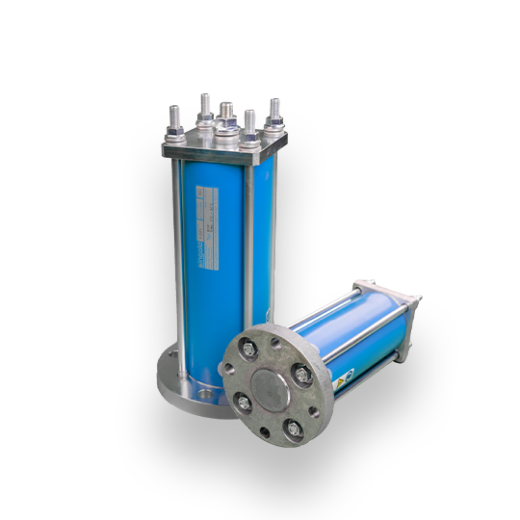

The pneumatic knocker works similarly to a silo hammer. It is useful whenever a product could be made to flow with a hand hammer and when vibrators or shakers are not effective. However, the pneumatic knocker does not cause dented silo outlets, which would further impede material flow.

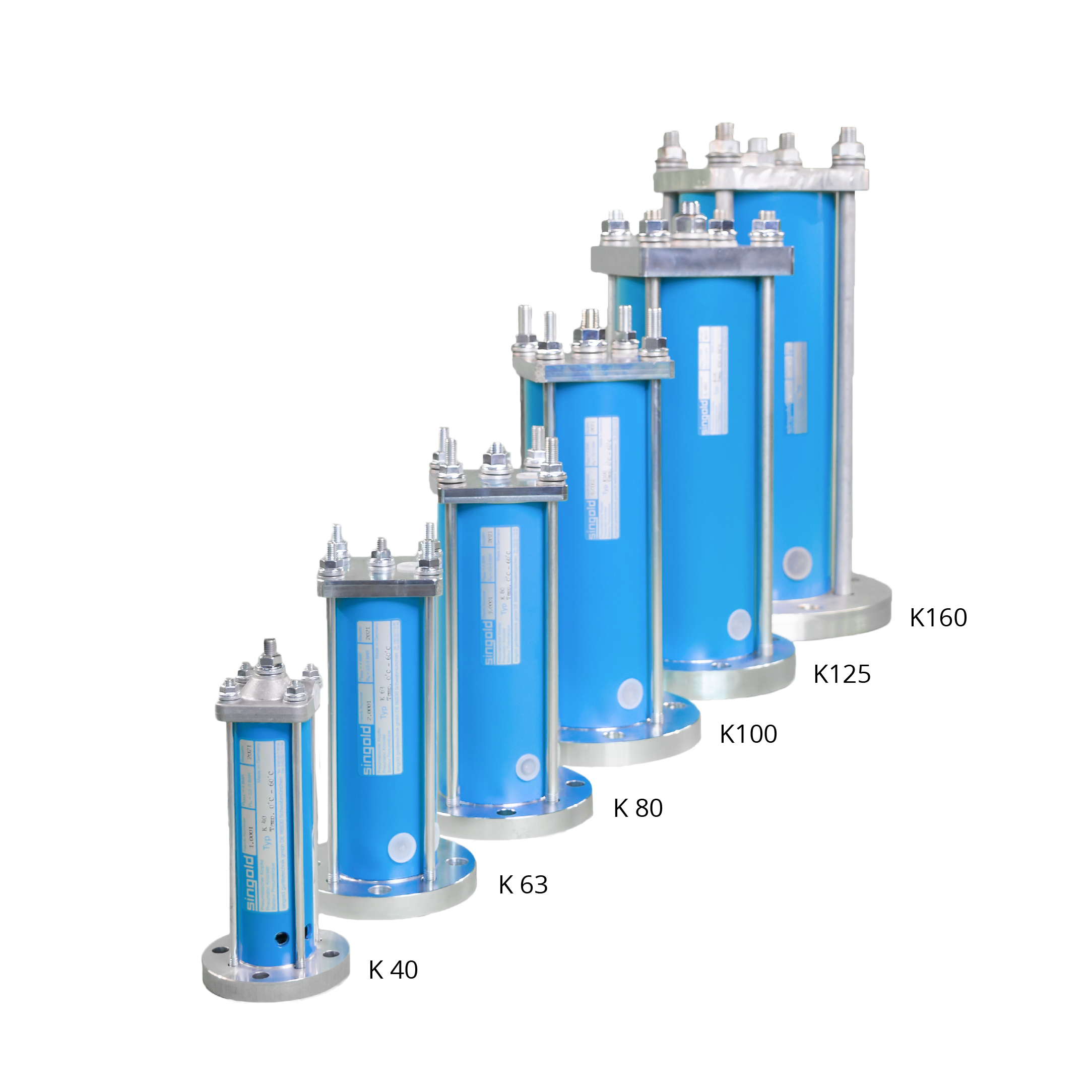

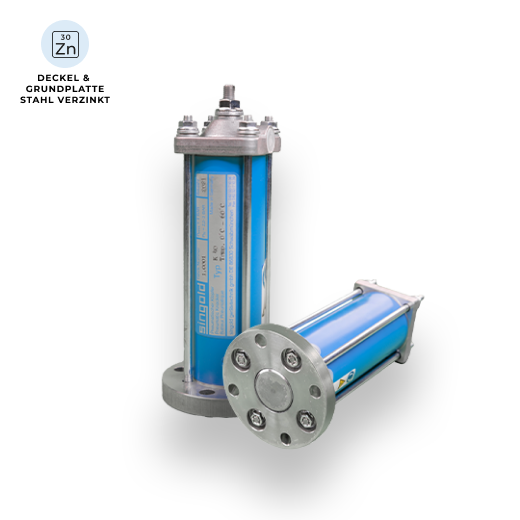

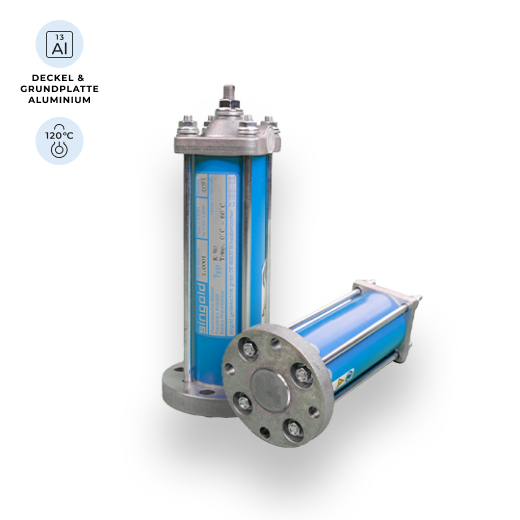

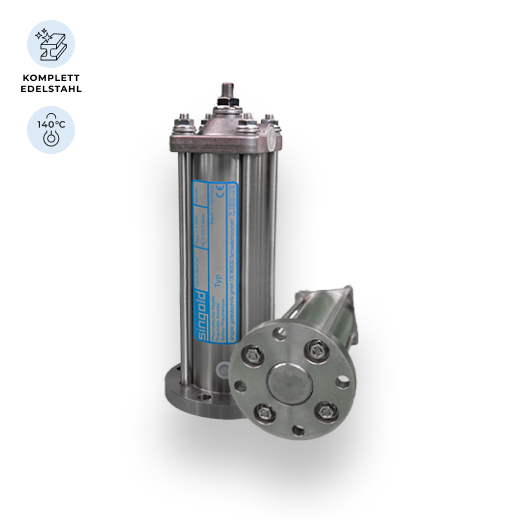

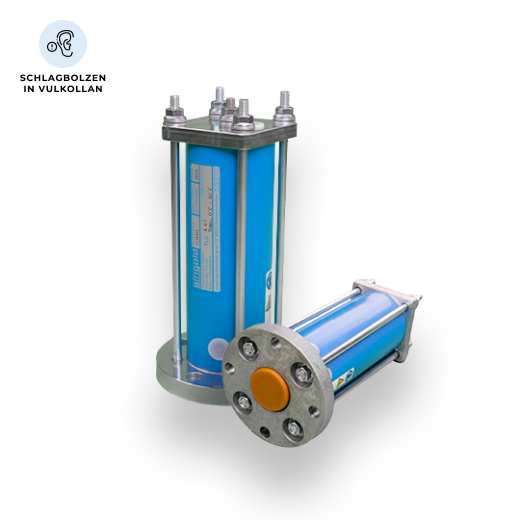

For our most frequently requested pneumatic knocker, Type K, we offer you a convenient online configurator here. With this, you can select the knocker that suits your needs and automatically start a request to us. If you are interested in the distance knocker Type QJ, please contact us directly.

Do you need assistance with the selection? We are happy to help!

Tel. +49 (0) 8232 50386-0

info@singold-tech.de