Highly efficient from a distance: The distance-knocker QJ from singold

When it is not possible to attach a pneumatic knocker directly to a silo, the pneumatic distance knocker from singold gerätetechnik gmbh offers a solution.

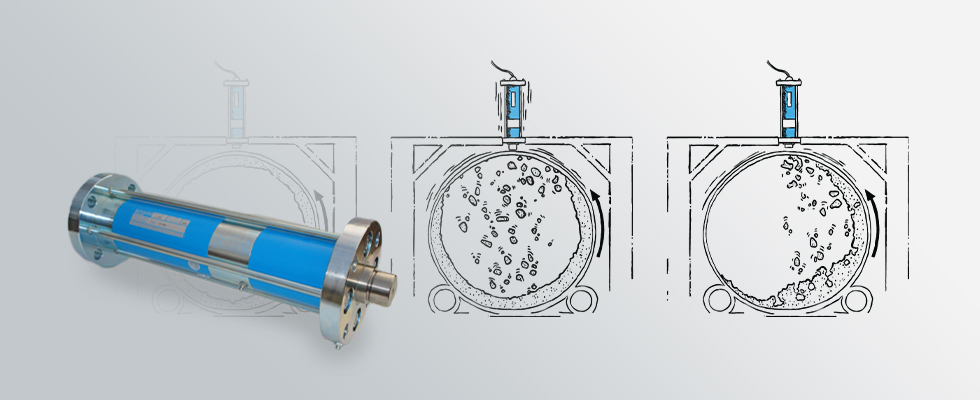

It is not always possible to attach a pneumatic knocker directly to a silo, for instance, if the container becomes hot or if it moves. In such cases, the pneumatic distance knocker from singold gerätetechnik gmbh offers a solution. Company founder Erwin Lüer developed it using state-of-the-art engineering.

How the Distance-Knocker QJ works

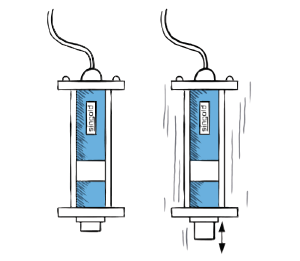

The basic concept is the same as that of the traditional pneumatic knocker: spontaneously released compressed air pressure accelerates the impact piston, which is designed as a permanent magnet, after it is released. In contrast to the conventional knocker, the distance knocker’s piston rod strikes a moving impulse part, which is strongly accelerated according to the impulse-momentum theorem and ultimately transfers the energy to the container to be knocked off. This process takes place at such a high speed that the human eye can hardly perceive it. Thanks to the additional impulse part, the Distance-Knocker QJ can be mounted at a distance from the silo; this means an enormous extension of the application possibilities.

A wide range of possible applications

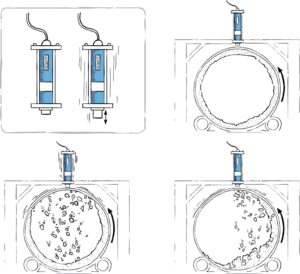

The distance knocker is always the method of choice when a successful cleaning can be achieved with a hammer blow but a classic knocker cannot be mounted directly on the container due to the temperature or movement of the object to be knocked off. This applies, for example, to filling and emptying stations with changing containers, rotating drums and silos with hot walls.

Use at high temperatures

Because of the spacing, the distance knocker can be used, for example, in rotary kiln drying systems with surface temperatures of up to 300 °C and more. The QJ is also suitable for automatically knocking off filter cups or filter baskets of different sizes. A design with a thread at the end of the piston rod even makes it possible for the impact body and thus the impact geometry to be adapted case-specifically to any conceivable application situation. For example, Vulkollan buffers at the end of the piston rod are available as accessories. This makes the distance knocker a valuable tool in many different industries and types of plants: from agriculture to powder metallurgy and steel production to the textile, pharmaceutical and food industries.

Suitable for the application

The optimal version for a company’s individual requirements depends on many parameters, such as the thickness of the sheet metal, the material and diameter of the container or the drum, as well as the operating temperature. The singold gerätetechnik gmbh service team advises on the selection of the ideally suited knocker and is happy to work out completely new application possibilities with creative application engineers.

How the Distance-Knocker QJ works

The basic concept is the same as that of the traditional pneumatic knocker: spontaneously released compressed air pressure accelerates the impact piston, which is designed as a permanent magnet, after it is released. In contrast to the conventional knocker, the distance knocker’s piston rod strikes a moving impulse part, which is strongly accelerated according to the impulse-momentum theorem and ultimately transfers the energy to the container to be knocked off. This process takes place at such a high speed that the human eye can hardly perceive it. Thanks to the additional impulse part, the Distance-Knocker QJ can be mounted at a distance from the silo; this means an enormous extension of the application possibilities.

Application example distance-knocker

Straightforward, functional and effective

The QJ knocks effectively – and only when needed

Compared to conventional ball housings, for example, the Distance-Knocker QJ produces about twenty times the impact energy. Another advantage of the distance knocker: while ball housings cannot be switched off when the drum is rotating, the QJ knocks on demand – i.e. only when it is needed for the process. This also benefits sound insulation and thus employee health.

The QJ can bridge these distances

The distance knocker is available in different sizes. The bridged distance to the element to be knocked off varies between 25 mm and 35 mm. In addition, the piston rod is available in an extended version that can increase the distance of the knocker to the container by another 200 mm. In the case of very hot walls in particular, it is necessary to set the distance between the knocker and the container as high as possible. The temperature of a knocker should not exceed 140 °C because otherwise the seals and other parts would wear out too quickly.

Simple construction – simple maintenance

As sophisticated as the invention of company founder Erwin Lüer is, it is nevertheless simple in design. For practical use, this means that the Distance-Knocker QJ is a low-maintenance tool in operation. Should a component ever need to be replaced, the knocker is simply disassembled and quickly reassembled.

We optimise your material flow

Contact us

Taking your individual situation into account, we are happy to assist you.